China prefab houses offer cost-effective, eco-friendly, and rapidly deployable building solutions for residential, commercial, and emergency projects. Leveraging advanced manufacturing and modular designs, these structures reduce construction time by 60-70% while maintaining high quality standards, making them ideal for global housing needs.

The Rise of Prefab Power: China’s Construction Game-Changer

Imagine building a fully functional home in under 10 days instead of months. That’s the reality with modern China prefab houses, where modular construction meets industrial precision. As global housing demands surge, China has emerged as the undisputed leader in prefabricated building technology, accounting for over 60% of worldwide prefab exports. But what makes these structures so revolutionary? It’s the perfect storm of engineering innovation, cost efficiency, and sustainable practices reshaping how we build.

Engineering Brilliance: Inside China’s Prefab Technology

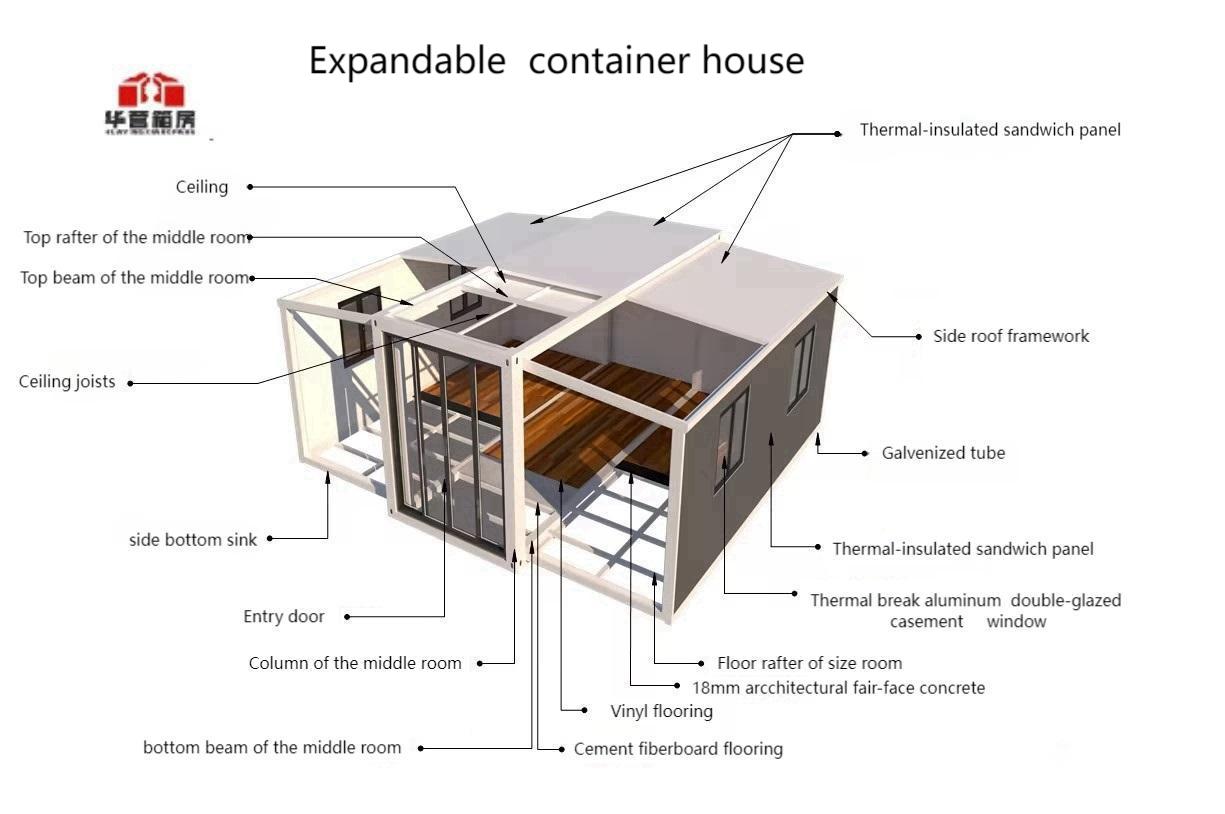

Chinese manufacturers like Huaying have perfected the science of modular construction through:

- Light Steel Frame Systems: Galvanized steel skeletons that resist corrosion and earthquakes

- Integrated MEP Channels: Pre-installed pathways for electrical and plumbing systems

- Composite Panel Innovation: EPS-core walls providing R-30 insulation values

- BIM-Designed Components: Digital modeling ensuring millimeter-perfect fittings

See the engineering mastery yourself in this structural diagram:

5 Compelling Advantages Driving Global Adoption

1. Unmatched Speed-to-Occupancy

Traditional construction timelines shrink dramatically with prefab houses. While site preparation happens, factories simultaneously manufacture modules. This parallel process means projects finish 60-70% faster than conventional builds. For commercial developers, this translates to earlier ROI – a game-changer for rental properties or hospitality ventures.

2. Budget-Friendly Construction

By centralizing production, Chinese prefabs achieve 30-40% cost savings through:

- Bulk material procurement

- Reduced on-site labor expenses

- Minimized construction waste (under 5% vs 30% in traditional builds)

3. Eco-Conscious Building

Prefab houses are sustainability champions. Closed-factory environments enable:

- Precise material optimization reducing carbon footprint

- Integration of solar-ready roofs and greywater systems

- Usage of recycled steel and VOC-free panels

4. Design Flexibility

From compact 20m² backyard studios to multi-story apartment complexes, modular units combine like architectural LEGO®. Clients customize:

- Floor plan configurations (open concept, partitioned rooms)

- Exterior finishes (wood-effect, modern metallic, traditional)

- Interior packages (basic to luxury smart-home setups)

5. Consistent Quality Control

Factory production ensures every component meets exacting standards before shipment. Climate-controlled manufacturing eliminates weather-related defects, while automated welding and CNC cutting guarantee structural precision.

See It to Believe It: Installation in Action

Witness how rapidly these structures go up! This timelapse shows a complete 80m² home installation:

Your browser does not support the video tag.

Where China Prefab Houses Shine: Real-World Applications

These versatile structures solve diverse challenges globally:

- Emergency Housing: Deployed within 72 hours for disaster relief

- Workforce Camps: Turnkey accommodations for mining/construction sites

- Urban Infill Housing: Solving density challenges in crowded cities

- Eco-Resorts: Low-impact tourism developments

- Educational Facilities: Scalable classroom blocks

A recent Ghana project saw 200 prefab housing units installed in 45 days – a task requiring 18+ months conventionally.

Navigating Your Prefab Project: Insider Tips

Maximize success with these professional guidelines:

- Select Tier-1 Suppliers: Verify ISO 9001, CE, and SGS certifications

- Plan Site Logistics: Ensure crane access and module delivery routes

- Optimize Foundation Design: Match base to local soil conditions

- Clarify Scope: Specify if you need turnkey or shell-only delivery

- Budget for Ancillary Costs: Factor in utilities hookup and local permits

The Future Is Modular: What’s Next for Prefab?

China’s prefab industry continues innovating with:

- 3D-printed modular components

- AI-assisted custom design platforms

- Blockchain-tracked material sourcing

- Smart-home integrated wall systems

As construction faces global labor shortages and climate pressures, prefab houses offer a sustainable, scalable solution. With Chinese manufacturers leading technological advances while maintaining competitive pricing, these structures are poised to dominate 21st-century building.