Discover how modular kit houses revolutionize homebuilding with cost-effective, eco-friendly construction. This comprehensive guide explores benefits, assembly processes, structural advantages, and ideal applications for these innovative prefabricated homes.

Ever dreamed of building your own home without the typical headaches? Modular kit houses are transforming the construction landscape, offering a smarter path to homeownership. Unlike traditional building methods, these prefabricated wonders arrive at your site as precision-engineered components, ready for streamlined assembly. Let’s explore why they’re becoming the go-to solution for savvy homeowners worldwide.

Why Modular Kit Houses Are Changing the Game

Imagine cutting your construction timeline by 40-60% while saving up to 20% on costs – that’s the modular advantage. These factory-built homes undergo rigorous quality control in climate-controlled environments, eliminating weather delays and material warping. Every beam, panel, and connector arrives with millimeter precision, ensuring a perfect fit during assembly. Beyond efficiency, modular homes are sustainability champions: factory production reduces waste by up to 90% compared to site-built homes, while integrated energy-efficient features like double-glazed windows and superior insulation slash long-term utility bills.

Behind the Scenes: How Modular Magic Works

The journey begins with customizable design options – from cozy studios to sprawling family homes. Once your design is finalized, manufacturing kicks off in specialized facilities where components are cut using CNC machines for surgical accuracy. Your kit ships with everything labeled and sequenced, including:

- Pre-insulated wall panels with wiring conduits

- Floor cassettes with integrated plumbing

- Roof trusses with pre-attached waterproof membranes

- Hardware kits with color-coded connectors

Assembly Simplicity in Action

Watch how easily components transform into living spaces. This time-lapse demonstrates a 800 sq ft module rising in just 3 days:

Your browser does not support the video tag.

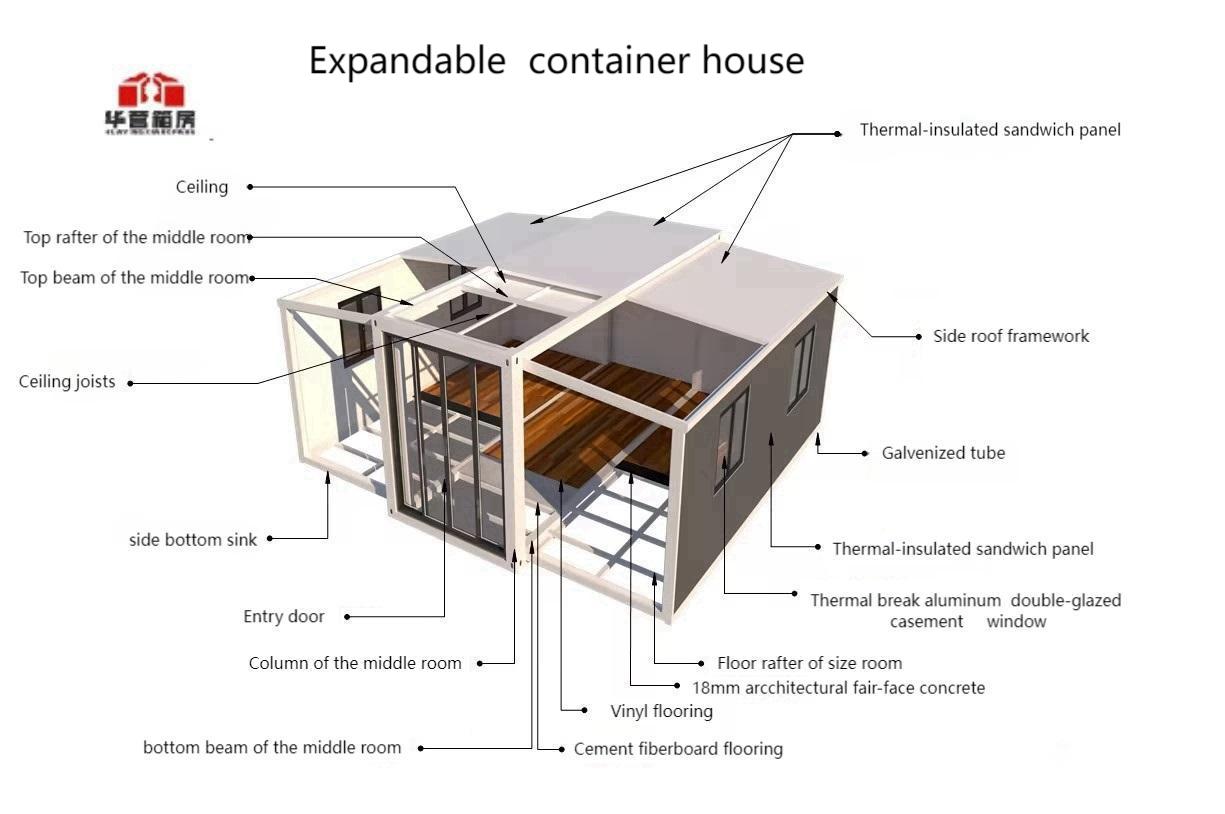

Engineering Excellence: What’s Inside Your Kit

Don’t mistake simplicity for fragility – these homes boast superior structural integrity. The secret lies in their panelized construction system, where stress-tested components interlock like 3D puzzles. Examine this cross-section revealing the smart engineering:

Notice the galvanized steel connectors at joints (Point A) that exceed local building codes, and the thermal-break technology (Point B) preventing energy leaks. The open-web floor trusses (Section C) allow easy plumbing/electricity runs while supporting 2.5x standard loads.

Who Should Consider a Modular Kit Home?

These versatile solutions cater to diverse needs:

- First-time homeowners: Build equity with 30% lower entry costs

- Remote property owners: Overcome logistical challenges with compact-packaged kits

- Eco-communities: Achieve net-zero goals with optional solar roof integration

- Vacation retreat builders: Erect guest cabins in weeks, not months

Sarah and Tom from Colorado shared: “Our 1,200 sq ft mountain cabin was assembled during summer break! The included manual made us feel like pros – we only needed contractors for foundation and electrical hookups.”

Smart Planning: Your Roadmap to Success

Ready to embark? Follow this checklist:

- Site Prep: Level land, pour foundation (6-8 weeks)

- Kit Delivery: Components arrive in logical sequence

- Assembly Phase: Bolt together main structure (1-3 weeks)

- Finishing Touches: Install interior finishes (2-4 weeks)

Pro Tip: Many manufacturers offer “hybrid” kits where you assemble the shell, then hire local trades for plumbing/electrical – perfect for DIY enthusiasts wanting professional-grade results.

Debunking 3 Common Myths

Let’s clarify misconceptions:

Myth 1: “They all look identical”

Reality: Modern CAD systems enable endless customization – swap wall panels for glass expanses, add dormers, or mix exterior finishes.

Myth 2: “Financing is impossible”

Reality: Major lenders now offer specialized “construction-to-permanent” loans for kit homes.

Myth 3: “They depreciate like mobile homes”

Reality: Appreciation mirrors conventional homes when permanently fixed to foundations.

The Future Is Modular

As construction technology advances, expect smarter kits featuring AI-assisted design tools and self-monitoring systems that alert you to maintenance needs. The modular revolution isn’t coming – it’s here, delivering quality-controlled, sustainable housing without compromise.

Whether you’re building a primary residence, backyard office, or emergency housing complex, modular kit houses offer unprecedented value. Why wait years for a traditional build when your dream home could be move-in ready next season?