Discover how prefabricated containers are revolutionizing the construction industry with their cost-effective, sustainable, and rapidly deployable solutions. This comprehensive guide explores the benefits, applications, installation process, and structural features of these innovative building systems that are changing how we think about construction.

In today’s fast-paced world, the demand for quick, efficient, and sustainable building solutions has never been higher. Enter prefabricated containers – the game-changers in the construction industry that are turning traditional building methods on their head. If you’ve ever wondered about those sleek, modern structures popping up in urban areas or at construction sites, chances are you’re looking at the brilliant work of prefabricated container technology.

What Are Prefabricated Containers?

Prefabricated containers, often called shipping container homes or modular container buildings, are essentially structures built using modified shipping containers. These containers are manufactured off-site in controlled factory environments before being transported to their final location for assembly. Think of them as high-tech building blocks that can be stacked, arranged, and customized to create virtually any type of structure you can imagine.

What makes these containers so special is their inherent strength, portability, and adaptability. Originally designed to withstand harsh ocean conditions while transporting goods across the globe, these steel boxes are incredibly durable and can be transformed into comfortable living spaces, offices, retail stores, and so much more.

The Benefits of Going Prefabricated

So, why are so many people and businesses jumping on the prefabricated container bandwagon? Let’s break down the key advantages:

- Speed of Construction: Traditional construction can take months or even years. With prefabricated containers, you can cut that time down to weeks or even days. Since most of the work happens off-site, weather delays are minimized, and on-site assembly is lightning fast.

- Cost-Effectiveness: Prefabricated containers typically cost 20-30% less than traditional buildings. The controlled factory environment reduces waste, and the streamlined manufacturing process keeps labor costs down.

- Sustainability: In an era where environmental consciousness is paramount, prefabricated containers shine. They often incorporate recycled materials, generate less construction waste, and can be designed for energy efficiency with proper insulation and solar panels.

- Flexibility and Mobility: Need to move your office or expand your living space? Prefabricated containers can be relocated with relative ease, offering a level of flexibility that traditional buildings simply can’t match.

Installation Process: As Easy as It Looks

One of the most impressive aspects of prefabricated containers is how quickly they can be installed. Don’t just take my word for it – check out this video demonstrating the installation process:

Your browser does not support the video tag.

As you can see, the installation process is remarkably straightforward. The containers arrive on-site already fitted with insulation, electrical wiring, plumbing, and interior finishes. A crane lifts them into place, where they’re secured and connected to utilities. What might take months with traditional construction is accomplished in a matter of days, minimizing disruption to the surrounding area.

Understanding the Structure

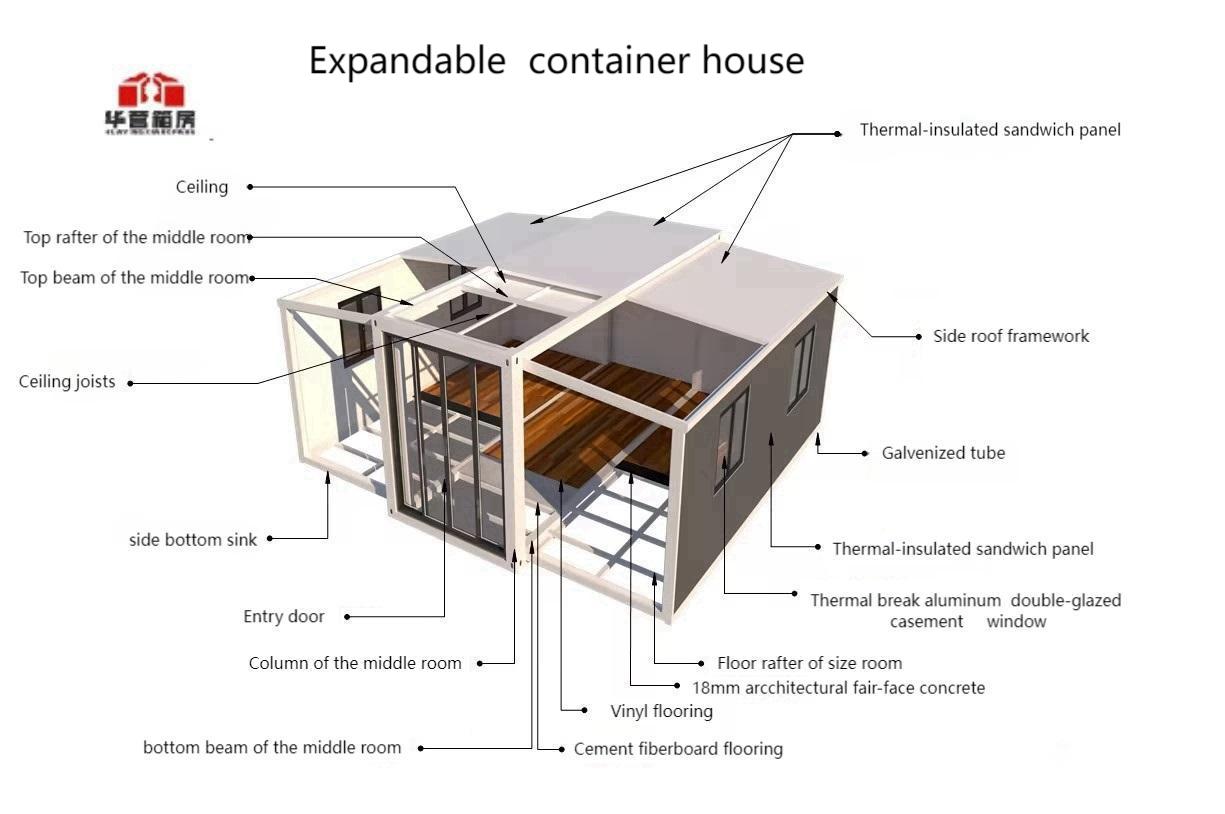

The structural integrity of prefabricated containers is one of their greatest strengths. Let’s take a closer look at how these buildings are constructed:

This diagram illustrates the innovative dual-wing structure that provides exceptional stability and allows for creative architectural designs. The steel frame forms the backbone of the structure, while reinforced corners and specialized connection points ensure that each container securely links to others. The result is a building that’s not only quick to assemble but also engineered to withstand extreme weather conditions and seismic activity.

Applications Across Industries

The versatility of prefabricated containers means they’re being used across virtually every sector:

- Residential: From tiny homes to multi-story apartment complexes, containers offer affordable housing solutions.

- Commercial: Pop-up shops, restaurants, and office spaces benefit from the quick deployment and modern aesthetic.

- Industrial: On-site offices, storage facilities, and worker accommodations are common uses in construction and resource extraction industries.

- Institutional: Schools, medical clinics, and emergency housing can be rapidly deployed in response to community needs.

- Event Spaces: Temporary venues for festivals, exhibitions, and sporting events leverage the portability of container structures.

Cost Considerations

While prefabricated containers are generally more cost-effective than traditional construction, several factors influence the final price:

- Size and Complexity: Larger structures and custom designs naturally cost more.

- Finishes and Features: High-end finishes, smart home technology, and specialized fixtures add to the cost.

- Site Preparation: The condition of the building site and necessary groundwork can impact the budget.

- Transportation: Distance from the manufacturing facility to the final location affects costs.

- Permits and Regulations: Local building codes and permit requirements vary by location.

On average, you can expect to pay between $150-$250 per square foot for a basic prefabricated container structure, compared to $200-$400+ for traditional construction.

The Future of Prefabricated Containers

As technology advances and sustainability becomes increasingly important, the future looks bright for prefabricated containers. We’re seeing innovations like:

- Smart containers with integrated IoT technology for energy management and security

- Advanced materials that improve insulation and reduce weight

- Automated manufacturing processes that further reduce costs and construction time

- Modular systems that allow for easy expansion and reconfiguration

Conclusion

Prefabricated containers represent more than just a building trend – they’re a practical solution to many of the challenges facing the construction industry today. With their combination of speed, cost-effectiveness, sustainability, and versatility, it’s no wonder they’re gaining popularity across the globe.

Whether you’re a homeowner looking for an affordable housing option, a business owner needing to expand quickly, or an organization responding to an emergency situation, prefabricated containers offer a modern, efficient solution that’s hard to beat. As we continue to push the boundaries of what’s possible with these remarkable structures, one thing is certain: the future of construction is here, and it comes in a container.