Sandwich panels are versatile, lightweight, and highly efficient building materials widely used in construction for their excellent insulation and structural properties. This comprehensive guide explores what sandwich panels are, their key benefits, common applications, easy installation process, and structural design, helping you understand why they’re a top choice for modern building projects.

If you’re involved in construction or renovation, you’ve probably heard of sandwich panels. These innovative materials are game-changers in the building industry, offering a perfect blend of strength, insulation, and ease of use. But what exactly are sandwich panels, and why should you consider them for your next project? Let’s dive in and explore everything you need to know about these fantastic panels.

What Are Sandwich Panels?

Sandwich panels, also known as composite panels, consist of three layers: two outer facings and an insulating core in between. The facings are typically made of materials like steel, aluminum, or fiberglass, providing durability and weather resistance. The core, often made of polyurethane (PUR), polyisocyanurate (PIR), or mineral wool, delivers exceptional thermal and acoustic insulation. This layered structure makes sandwich panels lightweight yet incredibly strong, making them ideal for a wide range of applications. Think of them as a sandwich—hence the name—where the core acts as the filling that holds everything together while adding value.

Key Benefits of Sandwich Panels

Why are sandwich panels so popular? Well, they come packed with advantages that make them stand out from traditional building materials. First off, they’re super lightweight, which means easier handling and reduced transportation costs. This also speeds up construction time, saving you money on labor. Plus, their insulation properties are top-notch. Whether it’s keeping heat out in summer or retaining warmth in winter, sandwich panels help maintain comfortable indoor temperatures, cutting down on energy bills. They’re also fire-resistant, especially those with mineral wool cores, enhancing safety in buildings. Durability is another big plus—these panels can withstand harsh weather, corrosion, and impacts, ensuring long-lasting performance. And let’s not forget versatility; they can be customized in various colors, finishes, and sizes to fit any design aesthetic.

Common Applications of Sandwich Panels

Sandwich panels are used in countless settings, thanks to their adaptability. In commercial and industrial buildings, they’re perfect for walls, roofs, and partitions, providing quick assembly and excellent insulation. For cold storage facilities like warehouses and refrigerated trucks, their thermal efficiency is unmatched, keeping temperatures stable. Residential projects also benefit—think of them for exterior cladding, garages, or even tiny homes, where their lightweight nature simplifies construction. Agricultural buildings, such as barns or greenhouses, use them to create controlled environments. Essentially, anywhere you need a balance of strength, insulation, and speed, sandwich panels are a go-to solution. It’s no wonder they’re a staple in modern architecture.

Installation Process Made Easy

One of the biggest selling points of sandwich panels is how easy they are to install. Unlike traditional materials that require complex setups, these panels can be assembled quickly with minimal tools. The process typically involves measuring, cutting, and securing the panels to a frame using screws or adhesives. No heavy machinery or specialized skills are needed, making it accessible even for DIY enthusiasts. To give you a better idea, check out this video that demonstrates the installation process. It shows how effortlessly the panels fit together, highlighting their user-friendly design. This not only saves time but also reduces labor costs, making your project more efficient overall.

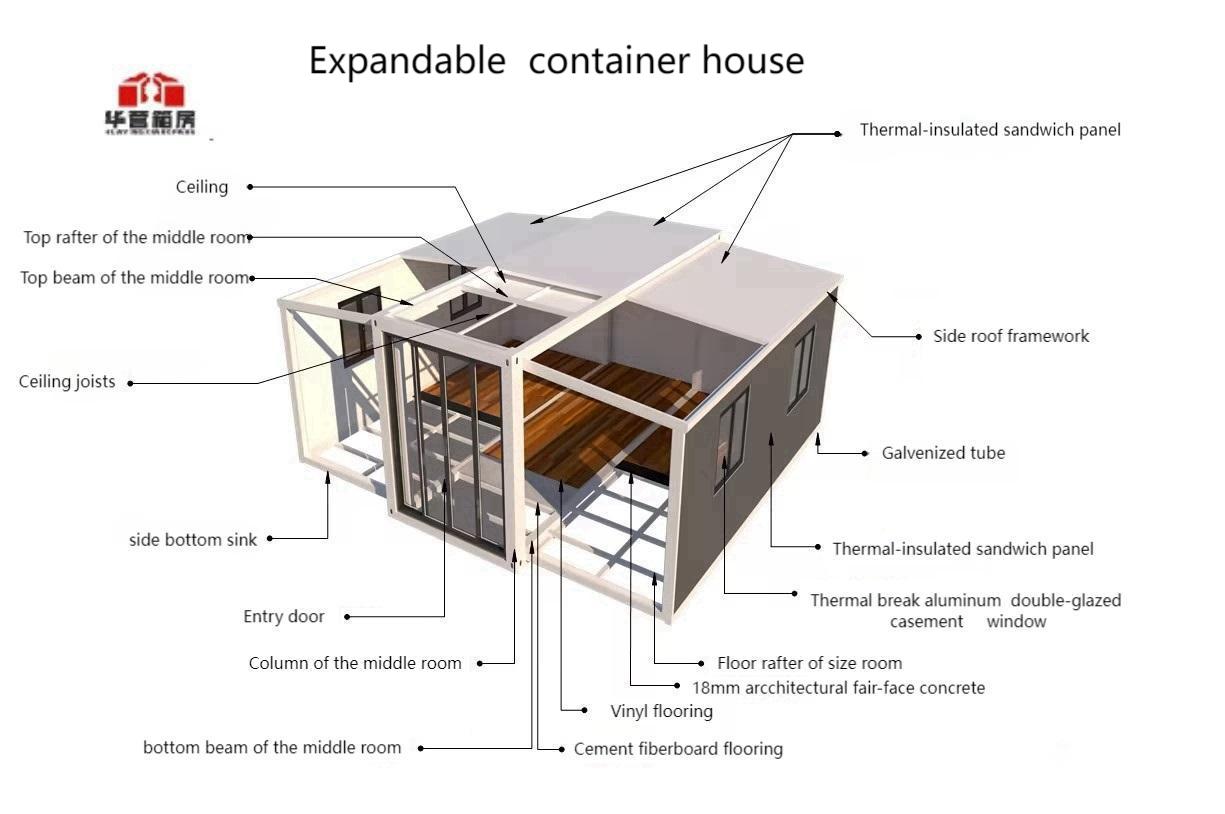

Understanding the Structure of Sandwich Panels

To truly appreciate sandwich panels, it helps to understand their internal structure. As mentioned, they have a core sandwiched between two facings, but the design can vary based on the core material and facing type. For instance, PUR or PIR cores offer high insulation with low weight, while mineral wool cores provide superior fire resistance. The facings are often coated for extra protection against UV rays and moisture. This structure ensures that the panels are not only strong but also efficient in thermal and acoustic performance. Take a look at this image that illustrates a typical sandwich panel structure. It clearly shows how the layers work together to deliver maximum benefits, from energy efficiency to structural integrity.

Why Choose Sandwich Panels for Your Project?

After exploring all these aspects, it’s clear that sandwich panels are a smart investment. They combine cost-effectiveness with high performance, making them suitable for everything from small renovations to large-scale constructions. By choosing sandwich panels, you’re opting for a material that’s eco-friendly, as it reduces energy consumption and waste. Plus, with their quick installation and low maintenance needs, you’ll enjoy peace of mind and long-term savings. Whether you’re a builder, architect, or homeowner, incorporating sandwich panels can elevate your project to new heights. So, next time you’re planning a build, give them serious consideration—you won’t be disappointed!