Prefab wooden houses revolutionize homebuilding with eco-friendly materials, rapid assembly, and customizable designs. This guide explores their structural advantages, installation process, cost benefits, and versatile applications—from backyard studios to primary residences—while addressing durability concerns and maintenance essentials.

Imagine moving into your dream home just weeks after ordering it. That’s the reality with prefab wooden houses, the construction industry’s best-kept secret for sustainable, efficient living. Unlike traditional builds, these structures arrive at your site as precision-engineered kits, slashing construction time by up to 70%. But what exactly makes them so special? Let’s dive in.

Why Prefab Wooden Houses Are Dominating Modern Construction

Prefabricated wooden homes combine centuries-old timber craftsmanship with cutting-edge manufacturing. Engineered wood panels (like CLT or glulam) offer incredible strength-to-weight ratios, while factory production ensures millimeter-perfect joints. This isn’t your grandfather’s log cabin—modern prefab wood houses meet strict international building codes for earthquake and hurricane resistance.

Environmental perks are equally impressive: wood sequesters carbon, and factory production reduces waste by 30% compared to onsite building. Plus, timber’s natural insulation properties can cut heating/cooling costs by 15-20%—a win for your wallet and the planet.

Anatomy of a Prefab Wood House: Precision in Every Panel

Ever wondered how these homes ship flat-packed yet assemble into robust structures? The magic lies in modular engineering. Walls, floors, and roofs are manufactured as insulated panels with pre-cut openings for doors, windows, and utilities.

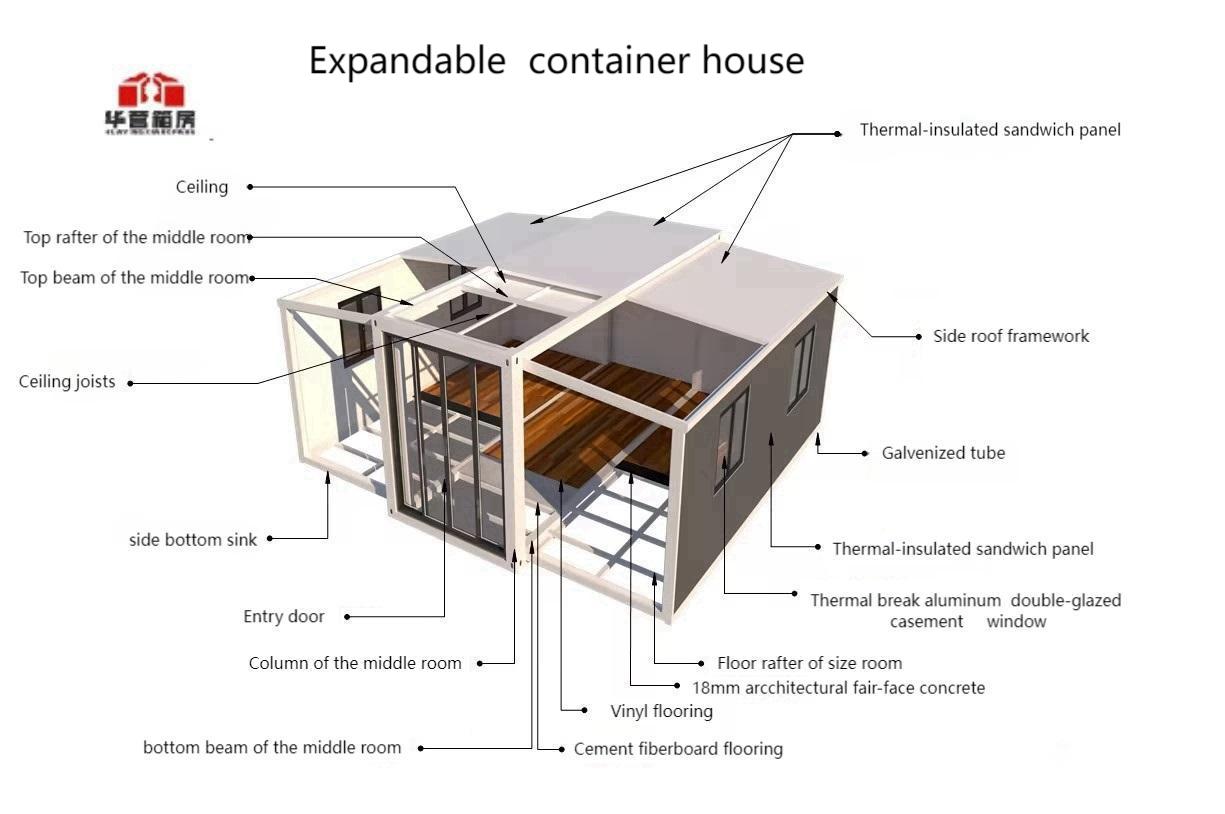

Image: Exploded view of prefab wood house components showing interlocking joints and insulation layers

Key structural elements include:

- Cross-Laminated Timber (CLT) Panels: Multi-layered wood sheets glued at right angles for dimensional stability

- Integrated Insulation: Wood fiber or recycled denim between structural layers

- Weather-Resistant Barriers: Built-in membranes behind exterior cladding

- Plug-and-Play Connectors: Color-coded joints for error-proof assembly

Watch It Go Up: Jaw-Dropping Installation Simplicity

The most mind-blowing aspect? How quickly these homes transform from crates to cozy retreats. Check this time-lapse of a 500 sq ft studio cabin assembled in just 3 days:

Real-world installation typically follows three phases:

- Foundation Prep (1-3 days): Concrete slab, piers, or basement

- Crane-Assisted Assembly (2-5 days): Wall/floor panels locked together like 3D puzzle pieces

- Weathertight Closure (24 hours): Roofing and windows installed

Pro tip: Many manufacturers offer DIY-friendly smaller models—no crane needed!

Beyond Backyard Cabins: Unexpected Applications

While garden offices and vacation cabins remain popular, prefab wood tech now powers sophisticated primary residences. Modern designs feature:

- Two-story family homes with open-plan living areas

- Net-zero energy units with integrated solar roofs

- Urban infill housing on narrow city lots

- Emergency shelters deployable within 48 hours

In Scandinavia, entire apartment complexes rise using prefab timber—proof this isn’t just a “tiny home” trend.

Debunking 3 Common Prefab Wood House Myths

Let’s tackle persistent misconceptions head-on:

- “They look cheap and boxy” → Modern designs feature soaring ceilings, floor-to-ceiling glass, and custom finishes rivaling custom builds.

- “Wood won’t last” → Pressure-treated timber and protective coatings ensure 50+ year lifespans. Japan’s Horyuji Temple proves wood endures—it’s stood for 1,400 years!

- “Limited customization” → Reputable manufacturers offer configurable layouts, exterior materials (metal, charred wood, composite), and interior partitions.

Smart Maintenance: Protect Your Investment

While low-maintenance, smart upkeep extends your home’s lifespan:

- Bi-Annual Check: Inspect sealants around windows/doors

- Stain Refresh: Reapply protective wood stain every 3-5 years

- Drainage Management: Keep gutters clear and soil graded away from foundations

Most manufacturers provide maintenance manuals tailored to local climates—whether you’re in rainy Seattle or sunny Arizona.

Cost Breakdown: Where You Save (and Spend)

Prefab wood houses typically cost 10-20% less than conventional builds, but expenses vary:

| Component | Traditional Build | Prefab Wood House |

|---|---|---|

| Construction Labor | $100-$150/sq ft | $60-$90/sq ft |

| Material Waste | 10-15% of materials | <5% of materials |

| Foundation | Equal cost | Equal cost |

| Finishes (custom tile, etc) | Variable | Variable |

The real savings? Time-related costs—secure financing for shorter terms and move in before rainy seasons!

Is a Prefab Wood House Right For You?

These homes shine for:

- Remote locations with limited contractor access

- Homeowners prioritizing sustainability

- Quick expansion projects (ADUs, guest suites)

- Budget-conscious builds without sacrificing quality

However, traditional construction may better suit highly irregular lots or those wanting daily onsite design tweaks.

As housing demands evolve, prefab wooden houses offer a compelling blend of speed, sustainability, and style. With shorter build times meaning lower loan interest and faster occupancy, it’s no wonder they’re moving from niche alternative to mainstream solution. Could your forever home be waiting in a flat-pack?